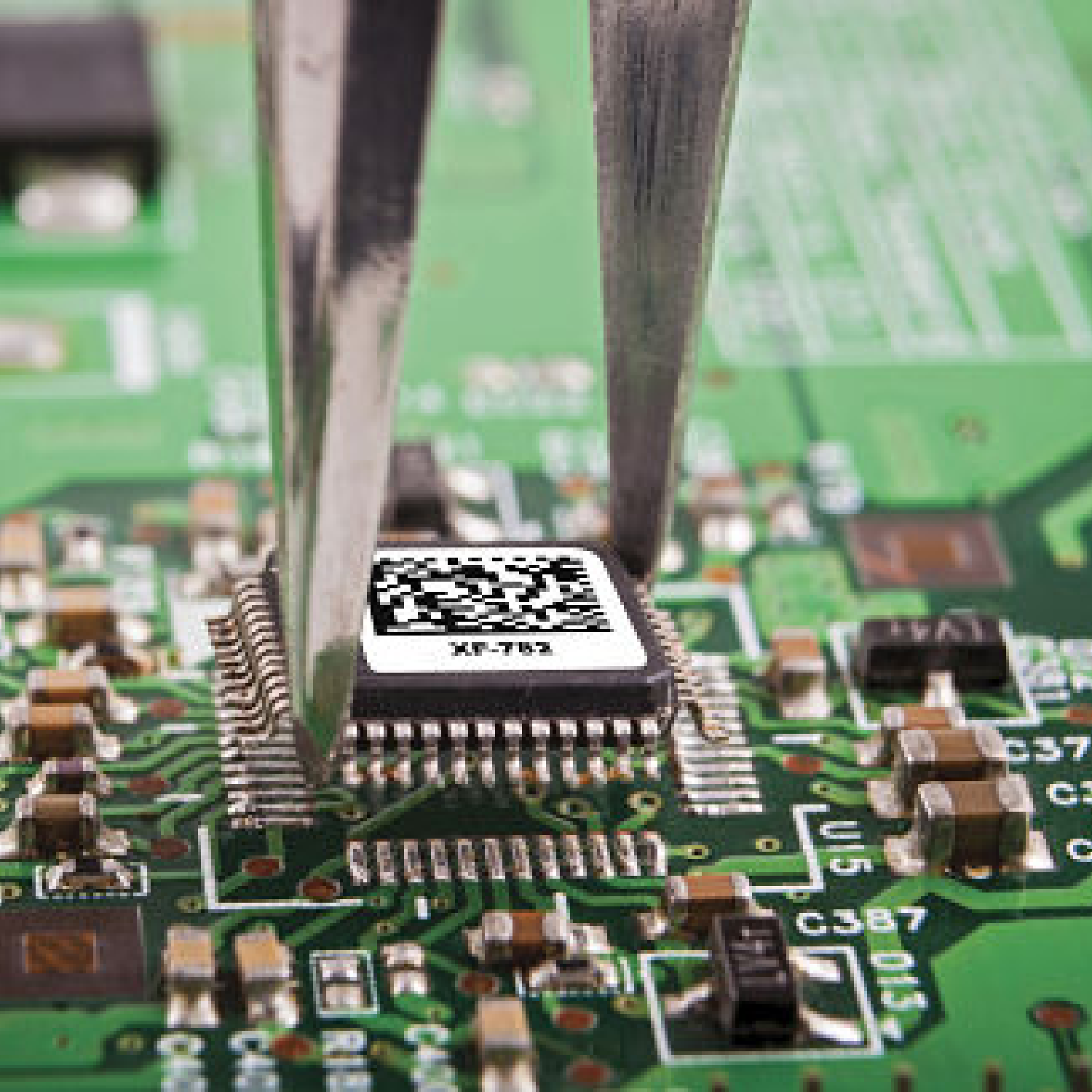

Electronic components power the devices that drive our daily lives—from smartphones and medical equipment to automotive systems and industrial controls. But these intricate parts, particularly microchips and printed circuit boards (PCBs), are extremely sensitive during production. Even small electrostatic discharges can cause component failure, reduce performance, and shorten product life cycles.

ID Label provides durable cleanroom labels and PCB barcode labels designed for the challenges of electronics manufacturing. Our antistatic labels protect sensitive components to help prevent ESD, while high-temp, solvent-resistant labels maintain adhesion and readability. They’re designed to reduce the charge generated when the label is removed from its liner, which could otherwise discharge and destroy sensitive components during application.

ID Label adheres to the industry Good Manufacturing Practices (GMP) to ensure our products are consistently produced and controlled according to industry quality standards. And both our PCB and cleanroom labels comply with the S20.20, 61340 and JESD625B federal and international standards for charged insulators used in the proximity of ESD-safe devices.

Related Products